Energy Conservation Analysis on Serpentine-tube ice maker

2020

Context

With the advancement of technology and improvements in living standards, ice makers have become essential household appliances, particularly in hot and humid regions where the demand for ice is high. This increased demand highlights the need for energy-efficient ice-making machines to reduce reliance on non-renewable energy sources and minimize environmental impacts. Enhancing the energy efficiency of ice makers is crucial for reducing operational costs and promoting sustainability. This research focuses on analyzing the performance of a typical batch-type ice maker to identify efficiency limitations and explore methods to improve energy conservation.

Content

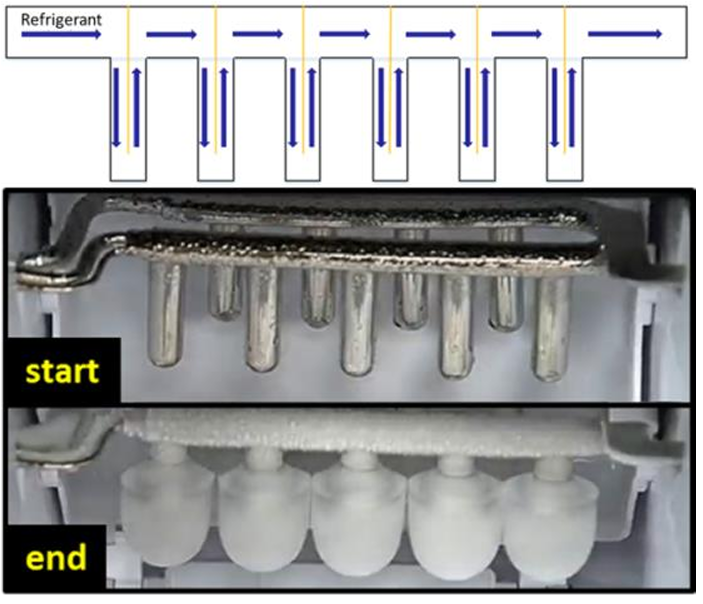

We investigated the performance of a batch-type ice maker using standard testing methods to identify efficiency limitations. The experimental setup involved measuring key parameters such as temperature changes in the evaporator and condenser, water temperature variation, ice production mass, and power consumption over continuous cycles. By analyzing the collected data, we calculated the sensible heat, latent heat, total heat, and coefficient of performance (COP) for each cycle. Our findings revealed that as the number of ice-making cycles increased, certain inefficiencies became apparent, such as uneven refrigerant temperature distribution leading to irregular ice sizes and reduced heat transfer efficiency. These issues were attributed to the design of the evaporator and the increased conduction resistance from thickened ice.

Conclusion

The study concludes that the current design of the batch-type ice maker has inherent limitations affecting its energy efficiency. Uneven refrigerant distribution and increased conduction resistance result in decreased heat transfer efficiency and a decline in COP over successive cycles. To enhance performance, we recommend structural modifications to the evaporator to ensure even refrigerant distribution, adequate spacing between ice-making tubes, and exploring alternative refrigerants or heat exchanger designs. Future research will focus on implementing these enhancements to develop more energy-efficient ice-making machines, contributing to energy conservation and aligning with global sustainability goals.